Tool steels water quenching: This group consists mainly of ordinary carbon steel; although some of the higher content steels carry small amounts of chromium and vanadium in order to increase hardenability and improve wear resistance. The carbon content of these steels ranges from 0.6 to 1.4% and can be subdivided in a general way by the percentage of carbon in the following subgroups. 0.6 to 0.75% carbon steels are used in these cases mainly interested tenacity, and hammers, riveting hammers, jackhammers, and headliners dies sprint.

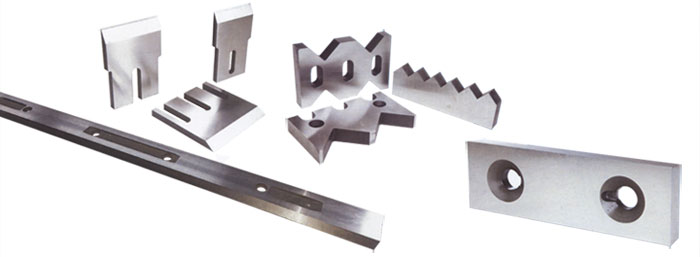

0.75 to 0.95% carbon, these steels are used for toughness and hardness and is needed in the punches, chisels, dies and shear blades. 0.95 to 1.4% carbon, these steels are used in cases where it is required to wear resistant tools and conservation conditions. They are used in the manufacture of woodworking tools, drills, reamers, taps and lathe tools.

Subjecting them to an appropriate heat treatment, it is possible to obtain a hard martensitic structure at the surface in hard core. To reach hardness figures are required, they must be tempered in water, and best machinability has better resistance to decarburization, although its thermal resistance is small.

The low alloy steel oil hardening contains minor amounts of manganese and chromium and tungsten. These steels represent high resistance to deformation and heat treatment because less likely to bend, praise, twist, warp or crack and the water quenching. Among its features we can mention its good wear resistance, machinability and resistance to decarburization; tenacity is only fair and hot hardness as low as that of the carbon tool steels. These steels are used in the manufacture of dies, roller rolling threads, form tools and expansive reamers.

Medium alloy steels containing about 1% carbon, 3% or less of manganese, at most 5% chromium and 1% molybdenum. The increased content of alloying elements, particularly of manganese and molybdenum steels gives these characteristic properties at very marked quenching air, and increase the hardenability. Steels of this group are characterized by excellent resistance to deformation is presenting a good wear resistance, toughness, and machinability ranging from fair to poor. They are used for cutting dies, embossing dies, thread rolling and rollers.

The high carbon steels containing chromium and up to 2.35% carbon and 12% of chromium, may also contain molybdenum, tungsten, vanadium and cobalt. The combination of carbon and high quantities of chromium provides excellent wear resistance and non-deformability. They are also characterized by its good resistance to abrasion and low size variation in the temple, which the punching of pictures for drawing wire, bar and tube, thread rolling rollers and measurement standards.

Buy Tool Steels Shear Blades Sheffield UK

Sheffield Gauge Plate Limited offers the best cutting tools and shear blades. If you want to buy the best quality products, visit Ground-Flat-Stock.co.uk or call at +44 114 2335291 to get free quotes.